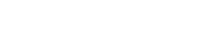

This 80ml safe and chemical-resistant PP bottle is an ideal companion for hair dye developers. Made from high-quality PP, it offers exceptional chemical resistance and effectively resists the chemical components in the developer, preventing leaching and bottle corrosion. This ensures product safety from the source, eliminating concerns about the packaging affecting the developer's quality.

The minimalist white design meets industry requirements for clean packaging while clearly displaying the contents. The simple style also facilitates subsequent processing, such as labeling, based on brand requirements, enhancing product recognition.

The 80ml capacity has been carefully considered to perfectly match the typical production and storage requirements of hair dye developers. Whether it's batch filling in the factory or daily storage, it can easily handle both, reducing the hassle of frequent bottle changes and improving work efficiency.

The bottle features an 80ml/12g/24-thread design. This detail ensures a precise fit with the matching cap, providing an excellent seal and effectively preventing the developer from leaking or deteriorating due to excessive exposure to air. This helps maintain stable and reliable product quality, providing strong support throughout production, transportation, and storage.

English

English Español

Español